Polyurethane Enameled Copper Clad Aluminium Hlau Class180

| Yam khoom | UAS/180 |

| Kev piav qhia dav dav | 180 Qib Ncaj Welded Polyurethane |

| IEC Cov Lus Qhia | IEC 60317-51, IEC 60317-20 |

| Qhov ntsuas kub (°C) | 180 |

| Solderability | 390 ℃ / 3s Solderable |

| NEMA Txoj Cai | MW 82, MW79, MW75 |

| UL-Kev pom zoo | YOG |

| Txoj kab uas hla muaj | 0.08mm-1.15 hli |

| Softening Breakdown Kub (°C) | 230 |

| Thermal Shock Kub (°C) | 200 |

| Nominal txoj kab uas hla (mm) | Conductor kam rau ua (mm) | G1 | G2 | Yam tsawg kawg nkaus tawg voltage (V) | Tsawg kawg elongation (%) | ||

| Yam tsawg kawg nkaus zaj duab xis thickness | Ua kom tiav qhov siab tshaj plaws sab nraud (mm) | Yam tsawg kawg nkaus zaj duab xis thickness | Ua kom tiav qhov siab tshaj plaws sab nraud (mm) | G1 | |||

| 0.1 | 0.003 ib | 0.005 ib | 0.115 ib | 0.009 ib | 0.124 ib | 1200 | 11 |

| 0.12 | 0.003 ib | 0.006 ib | 0.137 ib | 0.01 ib | 0.146 ib | 1600 | 11 |

| 0.15 | 0.003 ib | 0.006 5 | 0.17 ib | 0.0115 | 0.181 ib | 1800 | 15 |

| 0.17 ib | 0.003 ib | 0.007 ib | 0.193 ib | 0.0125 | 0.204 ib | 1800 | 15 |

| 0.19 ib | 0.003 ib | 0.008 ib | 0.215 ib | 0.0135 | 0.227 ib | Xyoo 1900 | 15 |

| 0.2 | 0.003 ib | 0.008 ib | 0.225 ib | 0.0135 | 0.238 ib | 2000 | 15 |

| 0.21 ib | 0.003 ib | 0.008 ib | 0.237 ib | 0.014 ib | 0.25 | 2000 | 15 |

| 0.23 | 0.003 ib | 0.009 ib | 0.257 ib | 0.016 ib | 0.271 ib | 2100 | 15 |

| 0.25 | 0.004 ib | 0.009 ib | 0.28 ib | 0.016 ib | 0.296 ib | 2300 | 15 |

| 0.27 ib | 0.004 ib | 0.009 ib | 0.3 | 0.016 5 | 0.318 ib | 2300 | 15 |

| 0.28 ib | 0.004 ib | 0.009 ib | 0.31 Nws | 0.016 5 | 0.328 ib | 2400 | 15 |

| 0.3 | 0.004 ib | 0.01 ib | 0.332 ib | 0.017 5 | 0.35 Nws | 2400 | 16 |

| 0.32 ib | 0.004 ib | 0.01 ib | 0.355 ib | 0.018 5 | 0.371 ib | 2400 | 16 |

| 0.33 ib | 0.004 ib | 0.01 ib | 0.365 ib | 0.019 ib | 0.381 ib | 2500 | 16 |

| 0.35 Nws | 0.004 ib | 0.01 ib | 0.385 ib | 0.019 ib | 0.401 ib | 2600 | 16 |

| 0.37 ib | 0.004 ib | 0.011 ib | 0.407 ib | 0.02 ib | 0.425 ib | 2600 | 17 |

| 0.38 ib | 0.004 ib | 0.011 ib | 0.417 ib | 0.02 ib | 0.435 ib | 2700 | 17 |

| 0.4 | 0.005 ib | 0.0115 | 0.437 ib | 0.02 ib | 0.455 ib | 2800 | 17 |

| 0.45 ib | 0.005 ib | 0.0115 | 0.488 ib | 0.021 ib | 0.507 ib | 2800 | 17 |

| 0.5 | 0.005 ib | 0.0125 | 0.54 ib | 0.0225 ib | 0.559 ib | 3000 | 19 |

| 0.55 ib | 0.005 ib | 0.0125 | 0.59 ib | 0.0235 | 0.617 ib | 3000 | 19 |

| 0.57 ib | 0.005 ib | 0.013 ib | 0.61 ib | 0.024 ib | 0.637 ib | 3000 | 19 |

| 0.6 | 0.006 ib | 0.0135 | 0.642 ib | 0.025 ib | 0.669 ib | 3100 | 20 |

| 0.65 ib | 0.006 ib | 0.014 ib | 0.692 ib | 0.0265 ib | 0.723 ib | 3100 | 20 |

| 0.7 ua | 0.007 ib | 0.015 ib | 0.745 ib | 0.0265 ib | 0.775 ib | 3100 | 20 |

| 0.75 ib | 0.007 ib | 0.015 ib | 0.796 ib | 0.028 ib | 0.829 ib | 3100 | 20 |

| 0.8 ua | 0.008 ib | 0.015 ib | 0.849 ib | 0.03 ib | 0.881 ib | 3200 | 20 |

| 0.85 ib | 0.008 ib | 0.016 ib | 0.902 ib | 0.03 ib | 0.933 ib | 3200 | 20 |

| 0.9 | 0.009 ib | 0.016 ib | 0.954 ib | 0.03 ib | 0.985 ib | 3300 ib | 20 |

| 0.95 ib | 0.009 ib | 0.017 ib | 1.006 ib | 0.0315 | 1.037 ib | 3400 ib | 20 |

| 1 | 0.01 ib | 0.017 5 | 1.06 ib | 0.0315 | 1.094 ib | 3500 | 20 |

| 1.05 Nws | 0.01 ib | 0.017 5 | 1.111 ib | 0.032 ib | 1.145 Nws | 3500 | 20 |

| 1.1 | 0.01 ib | 0.017 5 | 1.162 ib | 0.0325 ib | 1.196 ib | 3500 | 20 |

1. Cov khoom siv hluav taws xob zoo, zoo ib yam li tooj liab hlau ntawm qhov siab tshaj 5MHZ.

2. Txuag cov khoom siv tooj liab thiab txo cov nqi.Qhov ntom ntawm tooj liab clad aluminium hlau yog me dua li ntawm cov ntshiab tooj liab hlau, thiab nws qhov ntev yog 2.5 npaug ntawm cov hlau ntshiab tooj liab ntawm tib qhov hnyav.

3. softening breakdown kub yog siab tshaj UEW/155;ncaj soldering kub yog 390 ° C;yooj yim rau zas;tsis tshua muaj dielectric poob ntawm high zaus;tsis muaj dej ntsev pinhole

| Yam khoom | Kev piav qhia dav dav | Yam ntxwv |

| UAS/180 | 180 Qib Ncaj Welded Polyurethane | Softening breakdown kub yog siab tshaj UEW/155;ncaj soldering kub yog 390 ° C;yooj yim rau zas;tsis tshua muaj dielectric poob ntawm high zaus;tsis muaj dej ntsev pinhole |

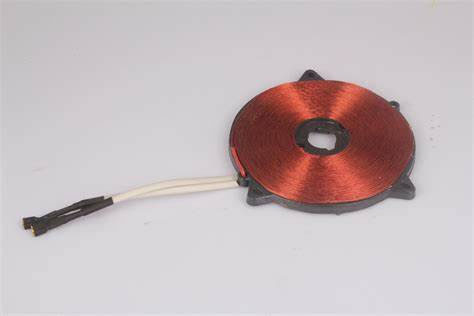

1.Relays, micro-motors, me me transformers, ignition coils, dej nres li qub, sib nqus taub hau, coils rau cov khoom sib txuas lus.

2.Transformer winding nyob rau hauv induction cooker.Nws tuaj yeem txo cov khoom hnyav.

3.Induction cooker chassis.Nws tuaj yeem txo cov nqi tsim khoom.

4. Sodium teeb ballast.Nws tuaj yeem txo cov khoom hnyav.

5.Ntau yam windings ntawm aerospace instruments.Nws tuaj yeem txo cov khoom hnyav.

6.Coils nyob rau hauv Induction Cooker Chassis, Nplhaib Transformer coils hauv High Fidelity Audio Equipment.

Bobbin Option

| Spool Hom | d1 [mm] | d4 [mm] | I1 [mm] | I2 [mm] | d14 [mm] | Lub cev hnyav [g] | npe.net hlau hnyav [kg] | pom zoo rau cov hlau loj [mm] | spools rau ib lub thawv | |||||

| Enameled tooj liab hlau | Enameled Aluminium Hlau | Enameled CCA Hlau | ||||||||||||

| 10% CCA | 30% CCA | 40% CCA | 50% CCA | |||||||||||

| PT-4 | 124 | 22 | 200 | 170 | 140 | 0.23 | 6 | 2 | 2.5 | 3 | 3.2 | 3.5 | 0.04-0.19 Nws | 4 |

| PIB-10 | 160 | 22 | 230 | 200 | 180 | 0.45 ib | 15 | 4.5 | 5 | 6 | 6.5 | 7.5 | 0.20-0.29 Nws | 2/4 |

| PIB-15 | 180 | 22 | 230 | 200 | 200 | 0.54 ib | 20 | 6.5 | 7 | 8 | 8.5 | 9 | 0.30-0.62 Nws | 1/2 |

| PIB-25 | 215 | 32 | 280 | 250 | 230 | 0.75 ib | 28 | 10 | 11 | 13 | 14 | 15 | 0.65-4.00 Nws | 1 |

| PIB-60 | 270 | 32 | 406 | 350 | 300 | 2.05 Nws | 80 | 24 | 24 | 28 | 32 | 35 | 0.65-4.00 Nws | 1 |

Ntim